By Keith Brown

•

December 5, 2025

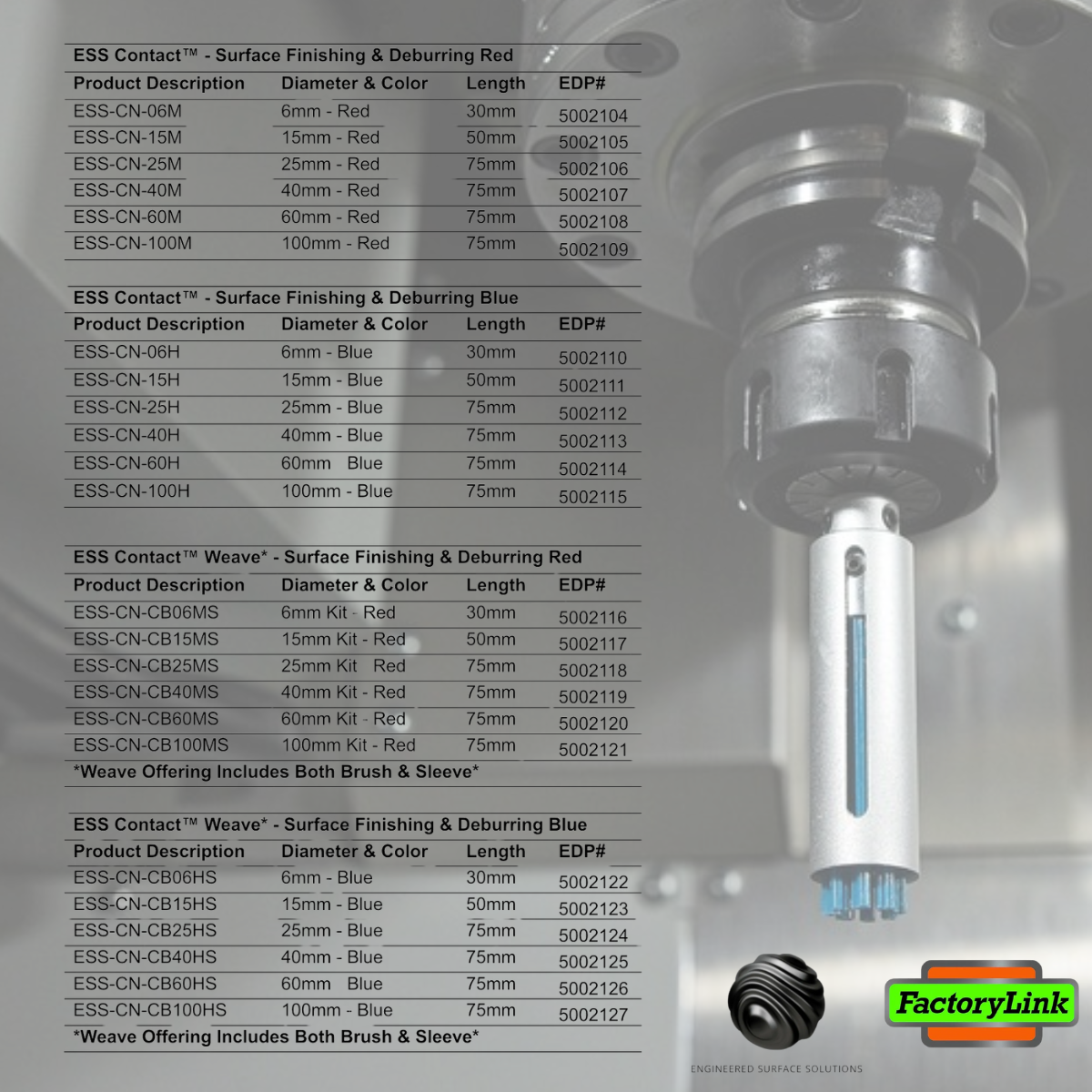

When it comes to industrial deburring, surface finishing, and high-precision internal tool solutions, E.S.S. (E SurfaceSolutions) remains the leader — and there’s only one official point of contact to get the real product, true specifications, and verified technical support. In manufacturing — especially when dealing with burr removal, tight tolerances, cross-section, or finishing tough materials — cut corners in communications or sourcing can introduce risk. A burr left behind isn’t just an aesthetic blemish — it can cause friction, premature wear, poor surface coatings, and even safety hazards. Using a single, verified contact prevents confusion and guarantees that you’re getting genuine E.S.S. solutions — with accurate specs, performance data, and support from the original source. What Sets ESS Apart E.S.S. specializes in mechanical and chemical surface enhancements , combining proprietary ceramic extruded fiber brush technology with deep-feature capability — ideal for challenging materials such as hardened steels (up to 70 HRC), stainless steels, super-alloys (Inconel®, Hastelloy®, Monel®, René alloys, Titanium), and more. Engineered fiber geometry delivers robust grinding power capable of removing burrs up to 0.010″ root thickness — and improves finishes while minimizing tool chatter and material stress. For surface-hole and deep-bore finishing, E.S.S. brushes outperform conventional media by “out-flexing” typical abrasive media while maintaining cutting pressure deep into features — reducing the need for manual “lollipop” tools or re-work. Compared to many incumbent solutions, E.S.S. often delivers 20–25% cost savings (due to longer tool life, faster cycle times, and reduced re-work), plus increased throughput and consistent part quality. For manufacturers looking for workflow improvement, reduced manual deburring, or precision-finished surfaces across aerospace, medical, firearms, automotive, or general machining — E.S.S. delivers tools built for accuracy, longevity, and repeatable results. As the Midwest representative, FactoryLink Inc. proudly supports E.S.S. with on-site demonstrations, product integration, training, and hands-on manufacturing solutions. If you need the right E.S.S. tool for your operation, Contact us FactoryLink Inc. for support. Either way — you’re connected to the same trusted network.