Introducing: The New Xebec Burrless Chamfering Cutter

The Xebec Burrless Chamfering Cutter: Key Features and Performance

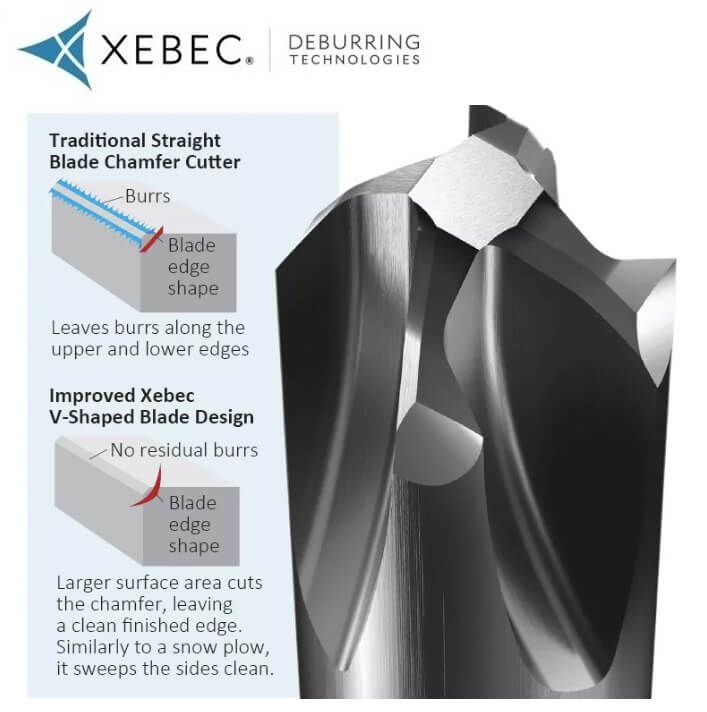

This chamfering tool offers the world’s first V-shaped blade, a patented technology from Xebec. It’s this blade type that enables the tool to prevent burrs during the chamfering process. It cuts a clean, finished, burr-free chamfer. With this, you can eliminate the deburring process and shorten cycle time – saving on labor and tool costs.

The cutter is designed with multiple blades, which enables a high feed rate and reduced machining time, and a flat tip, which prevents rounding and chipping of the tool.

Our chamfer cutter is made from Micro-Grain Cemented Carbide, and it’s available Coated with a heat-resistant AITiCrN coating or Uncoated with a sharper edge suited for aluminum alloys and plastics.

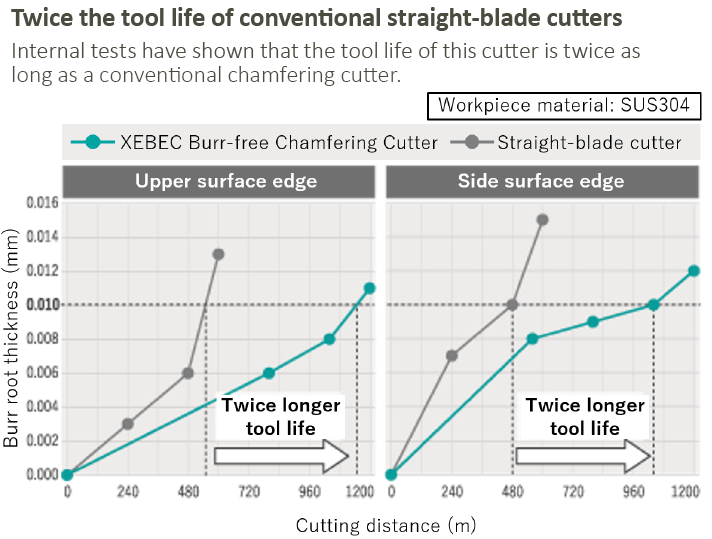

The tool also lasts twice as long as conventional straight-blade cutters, as proven by internal tests. This longer tool life is another way the chamfer cutter saves on tool costs. applied to a raw corner rather than a chamfered edge.

For chamfered (and rounded) edges with critical tolerances, machining is the best solution. And as with any cuts to metal and other materials used in manufacturing, any resulting secondary burrs from chamfering must be removed.

Types of parts that need chamfered edges include:

- Engine blocks

- Manifolds

- Golf clubs

- Turbines

- Firearm components

Read More:

https://deburringtechnologies.com/introducing-the-new-xebec-burrless-chamfering-cutter/