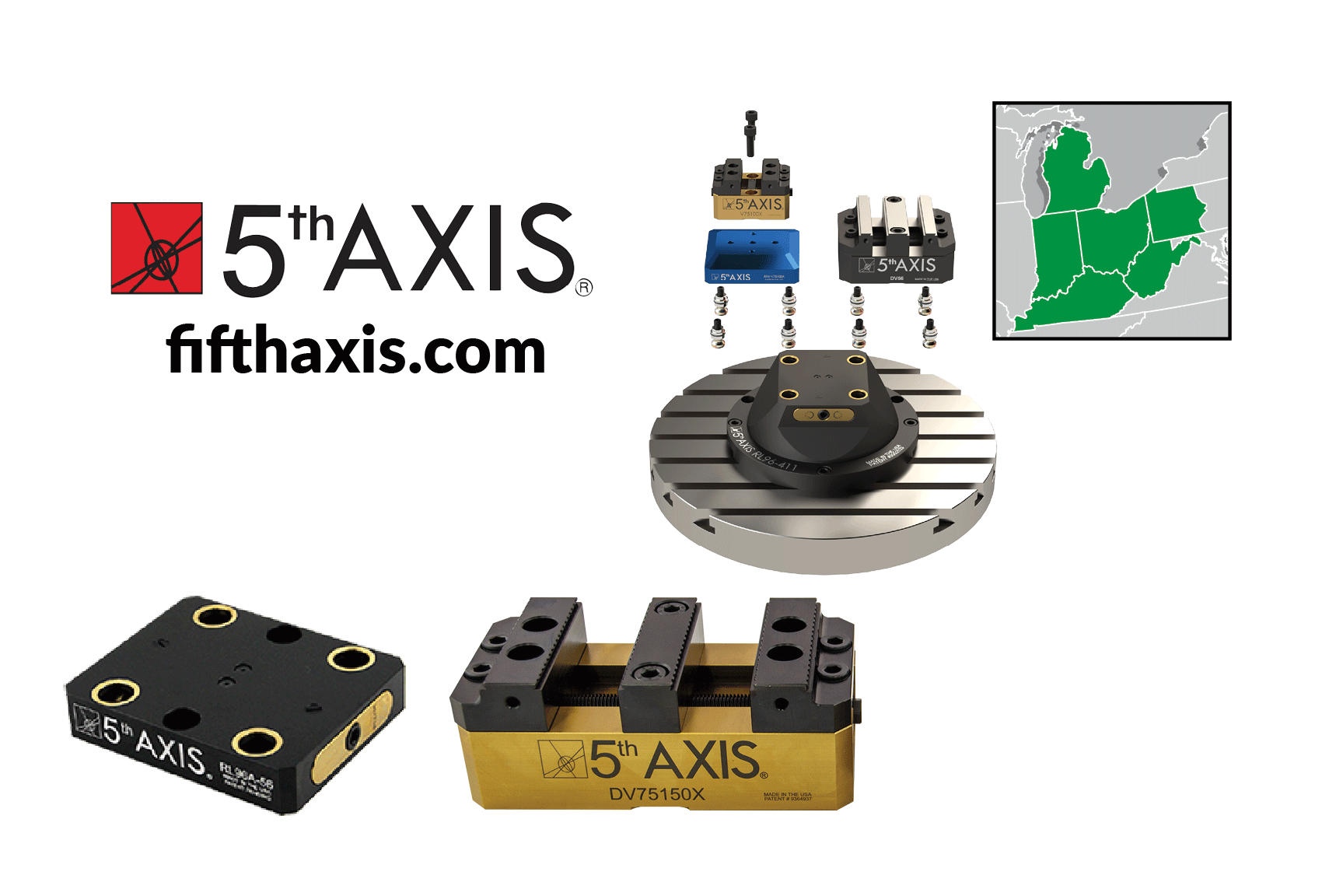

FactoryLink is Proud to Represent 5th Axis Modular Workholding

Modular workholding systems are becoming increasingly popular in manufacturing and machining industries, and for good reason. These systems offer a range of advantages for end-user customers, including:

1. Flexibility: Modular workholding systems are designed to be adaptable and can be easily reconfigured to accommodate different parts and production runs. This means that manufacturers can quickly switch between different products and production processes, reducing downtime and increasing efficiency.

2. Customization: Modular workholding systems can be tailored to meet the specific needs of each customer. This allows manufacturers to create customized solutions that are optimized for their specific production processes and parts.

3. Improved accuracy: Modular workholding systems are designed to provide consistent and repeatable results, which is essential for maintaining accuracy and quality in machining and manufacturing processes.

4. Reduced setup times: Modular workholding systems are designed to be quick and easy to set up, reducing the time and effort required to prepare for production runs.

5. Increased productivity: With modular workholding systems, manufacturers can process multiple parts at once, increasing productivity and reducing cycle times.

6. Cost savings: Modular workholding systems can help reduce costs by minimizing the need for additional fixtures and tooling.

7. Improved safety: Modular workholding systems are designed with safety in mind, reducing the risk of accidents and injuries in the workplace.

8. Easy maintenance: Modular workholding systems are designed to be easy to maintain and repair, reducing downtime and extending the life of the equipment.

9. Scalability: Modular workholding systems can be easily scaled up or down to meet changing production demands, making them an ideal solution for manufacturers who need to adapt to changing market conditions.

10. Improved customer satisfaction: By providing manufacturers with the ability to produce high-quality products quickly and efficiently, modular workholding systems can help improve customer satisfaction and loyalty.

In conclusion, FactoryLink's 5th Axis modular workholding systems offer a range of advantages for end-user customers, including flexibility, customization, improved accuracy, reduced setup times, increased productivity, cost savings, improved safety, easy maintenance.

Visit our website to schedule a call with our technical support team to learn more about how we can assist with your workholding needs.

Want more information?

1 (740) 392-0330

5 Harrison Avenue

Mount Vernon, OH 43050

Latest news